Ball Mill Grinding Ball

Introduction of Grinding Balls

Ball mill grinding balls are both types of grinding media used in the process of mineral processing and ore grinding. They have different shapes and properties, which make them suitable for various applications in comminution processes.

Ball Mill Grinding Balls

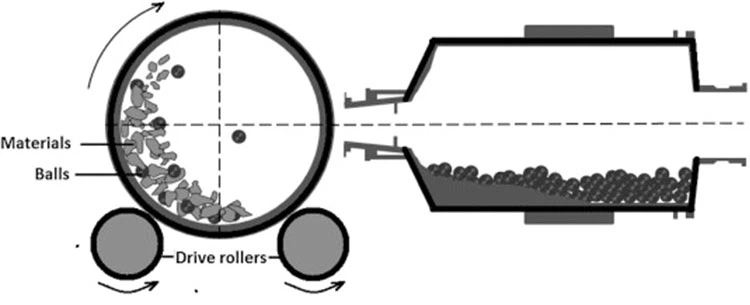

Ball mill grinding balls are spherical balls made of steel, ceramic, or other materials. They are used in ball mills, which are rotating cylindrical drums that contain grinding media (balls) and the material to be ground. When the ball mill rotates, the grinding balls collide with the material, crushing and grinding it into fine particles. The size and composition of the grinding balls can vary to suit the specific requirements of the milling process and the material being processed. Ball mill grinding balls are commonly used in industries like mining, cement, and other mineral processing applications.

Rod Mill Grinding Rods

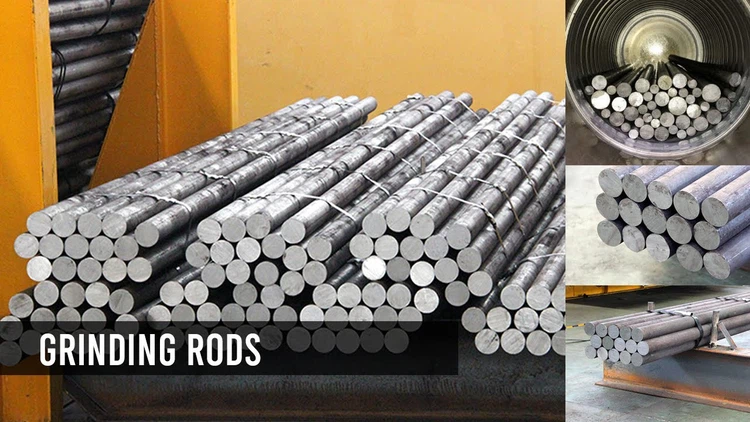

Grinding rods, also known as grinding media rods or mill rods, are long cylindrical rods made of steel or other materials. They are used in rod mills, which are similar to ball mills but use rods instead of balls as the grinding media. The grinding rods are used to grind the ore by tumbling within the mill, and they have a higher surface area to aid in the grinding process. Grinding rods are typically used in the mining industry for grinding minerals.

What are the types of mill balls and mill rods?

1.Rolled balls

Rolled balls also known as forged balls are made from our custom grade raw materials.offers traditional forged ball products to customers whose diameter requirement is more than 125 mm or who have special requirements.

The ball size is uniform and that they have a smooth surface. We ensure that each ball is subject to strict quenching and tempering heat treatment regimes. We ensure uniformity in outer hardness and inner toughness, which gives excellent impact resistance, toughness and durability to the product.

Results achieved after inspection indicate that the spherical hardness and volume hardness of the grinding ball meet the standards required in HRC58-65, and that the impact toughness is greater than 15 j/cm2. The drop test is carried out more than 10000 times, while the actual crushing rate is lower than 0.5%.

2.Traditional cast-iron balls

Forged grinding balls have excellent toughness, preserve their circular shape, low wear and tear, and a low crushing rate.It is widely used in a variety of dry mills.

Chromium forged balls are widely used in powder preparation, and ultra-fine powdering of cement, metal ores and coal slurries. They are used in thermal power, chemical engineering, ceramic paint, light industry, papermaking and magnetic material industries, besides others.

The hardness of our high chromium ball product is 56–62 HRC, the hardness of medium chromium ball is up to 47–55 HRC, while the hardness of the low chromium ball is up to 45–52 HRC, with 20 mm as the minimum and 120 mm as the maximum diameter.

3.Grinding Rod

Grinding rods, are cylindrical rods used as grinding media in rod mills for ore grinding.

They are subject to special heat treatment,which ensure low wear and tear, high levels of hardness (45–55 HRC), excellenttoughness and wear resistance which is 1.5–2 times that of ordinary material.

After quenching and tempering,the rod exhibits good features of non-breaking and straightness without bending, as well as, absence of tapering on the two ends.Good wear resistance reduces costs greatly for customers.

The latest production techniques are used, and the size and specification of products can be provided exactly as per the customer's requirement.

How To Choose The Mill Balls

The choice between using balls or rods depends on the specific requirements of the milling process and the properties of the material being ground. Both types of grinding media play a crucial role in reducing the size of the ore particles during the grinding process.

Here are some key factors to consider when selecting mill balls:

1.Material: Mill balls are commonly made of steel, stainless steel, ceramic, or other materials. Steel balls are suitable for most general milling applications, while ceramic balls are used for grinding sensitive materials. Consider the hardness, density, and wear resistance of the material to match the milling requirements.

2.Size: The size of the mill balls influences the grinding efficiency and final particle size. Larger balls are suitable for coarse grinding, while smaller balls are better for fine grinding. Choose the appropriate ball size based on the mill type and desired output.

3.Ball Charge and Loading: The ball charge ratio (the proportion of mill balls to the material) and loading (percentage of the mill volume filled with balls) impact the milling performance. Optimize these parameters to achieve the desired grind and throughput.

4.Milling Environment: Consider the milling environment, such as pH level, temperature, and corrosiveness, when choosing the ball material. For example, corrosive environments may require stainless steel or ceramic balls.

5.Cost and Durability: Balance the cost of the mill balls with their expected lifespan. High-quality balls might be more expensive but can offer longer-lasting and more consistent performance.

6.Supplier Reputation: Choose reliable suppliers with a track record of providing high-quality mill balls. Check for certifications and customer reviews to ensure the balls meet industry standards.

It is advantageous to source hot rolled steel balls, manufactured using rotary cutting and roll forging, from Great Wall Machinery because of the guaranteed fast delivery, large production and consistent quality, making this an especially suitable proposition for long-term procurement. Thanks to our annual steelmaking capacity of 500,000 tons of various forged products, greatwall can source raw material customized as per your exact requirements directly from reputed steel mills in China, and manufacture all kinds of alloy steel for your grinding ball requirements.

Hot Tags: Ball Mill Grinding Ball, China Ball Mill Grinding Ball manufacturers, suppliers, factory, Crusher Hammer Head, Ball Mill Parts, Mantle And Concave, Spare Parts, Rotary Kiln Parts, Crusher Spare Parts

Previous

No InformationYou Might Also Like

Send Inquiry